Extended storage reveals concerning rots

By Noel Ainsworth, Queensland Department of Agriculture and Fisheries

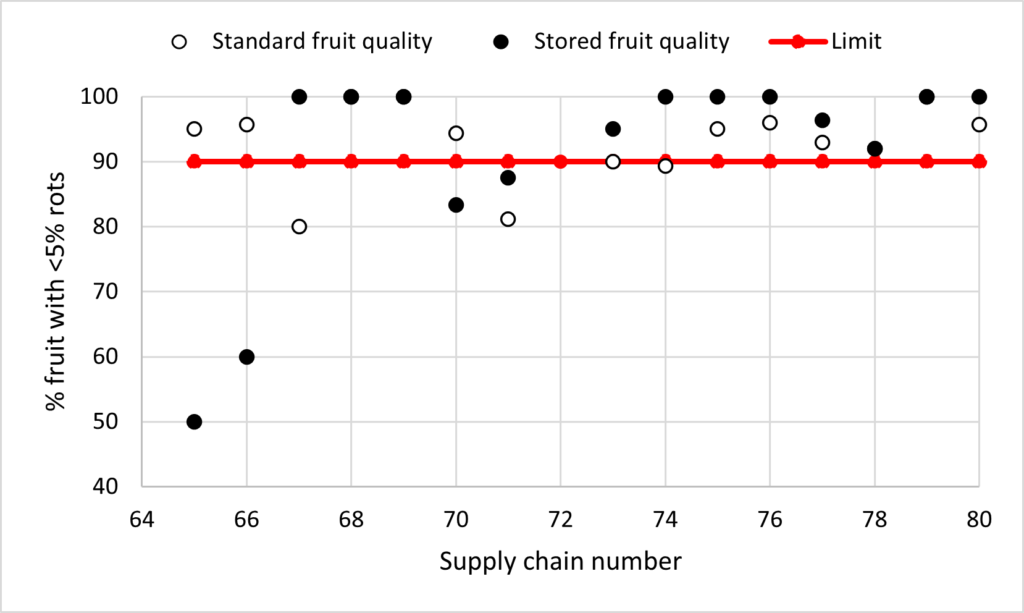

What is the impact of extended storage on fruit quality? The AV18000 project found that in most cases – 67% – this made no difference to the ripe fruit quality, but in some cases (20%), the fruit quality was considerably worse.

Duplicate samples of fruit from consignments from the same farm and picked on the same day were examined. The quality of fruit samples stored for two weeks (pre-ripening) were compared with those that passed through the chain under normal supply chain arrangements. This involved fruit monitored recently in West Australian and North Queensland consignments. Figure 1 shows ripe fruit quality results for standard supply chains versus those given an additional 14 days of storage. Findings suggests that in some cases, there might be practices which put the fruit at risk of developing rots if extended storage is part of supply chains. Examples of how this might happen include when the market is congested with fruit, or if the fruit is being selected for extended supply chains for export markets.

Figure 1. Comparison of ripe fruit quality results for standard supply chains versus those given an additional 14 days of storage.

Best practice for avocado supply chain procedures identifies that providing fruit is promptly cooled after harvest and during transport, then hard green fruit can be stored for up to 14 days before ripening. This coincides with advice that suggests rots including body rots and stem end rots invade rapidly after the fruit passes 25 days since harvest. For the past two years of monitoring supply chains, most fruit have reached eating ripe within 15 days of harvest. The extended storage treatment, as part of the AV18000 avocado supply chain feedback project, is seeking to identify those consignments at risk of poor fruit quality, should their normal supply chains be extended.

The differences between supply chains can be illustrated in Table 1 showing how these numbers translate to images of the fruit at ripe fruit quality assessment.

| Supply chain no. 77 | Supply chain no. 65 | |

|---|---|---|

| Standard supply chain |  |

|

| Standard plus 14 days storage |  |

|

| Likely reason for the difference | Robust fruit showing no difference with standard sample recording of 92.9% and 96.4% acceptability in the sample with 14 days storage. | Fruit not treated with any post-harvest fungicide dropping from 95% acceptability to 50%. |

Table 1. Comparison of Hass fruit quality for two supply chains, with and without 14 days of additional pre-ripening storage at 5˚C.

The comparison in Table 1 reinforces the value of postharvest fungicides in reducing the development of rots, especially in fruit exposed to supply chains of longer than 25 days. This can help address the risk of unknown supply chain length when supply in Australia is rising more quickly than demand, and resultant prices favour a greater proportion of production being directed to export markets.

In the BPR

You can find more information on temperature management, postharvest treatments and other related topics in the Packhouse, Transport, Wholesale and Ripening modules of the BPR. (Don’t have BPR access? Click here to apply. The BPR is available for Australian-based members of the avocado industry.)

More information

Noel Ainsworth, Principal Supply Chain Horticulturist, Department of Agriculture and Fisheries, Mobile 0409 003 909, Email noel.ainsworth@daf.qld.gov.au

The AV18000 project has been funded by Hort Innovation, using the Hort Innovation avocado industry research and development levy, co-investment from the Queensland Department of Agriculture and Fisheries, the Western Australian Department of Primary Industries and Regional Development and contributions from the Australian Government. Hort Innovation is the grower-owned, not-for-profit research and development corporation for Australian horticulture. Key project delivery partners also include Avocados Australia Ltd and Rudge Produce Systems.

Date Published: 21/07/2021