Reducing the impact of departure temperature on fruit quality

Increases in supply chain times may occur in coming months with consistently high supply and the potential for disruptions to logistics. Increased storage time in the supply chain can occur both prior to and post ripening and lead to higher fruit age.

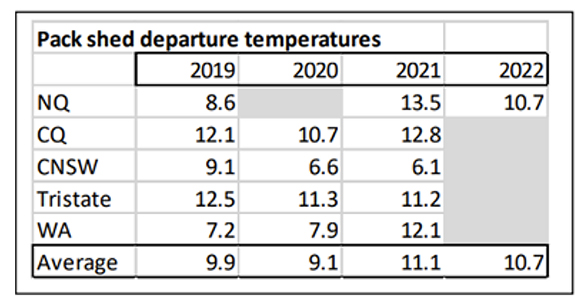

The impact of longer supply chains on fruit quality can be considerable depending on the pack shed departure temperatures of consignments. Previous supply chain project (AV18000) identified that packhouse departure temperatures are generally not meeting best practice recommendations (5°C for Hass and 7°C for Shepard) for 76% of samples. Average departure temperatures have ranged from 9 to 11°C in recent years (Figure 1 below).

Relatively short avocado supply chains of less than 2 weeks can mask the impact of less-than-ideal consignment temperatures, but once the market conditions see fruit age increase, fruit defects increase markedly (Figure 2 below).

a) Good quality fruit when ripened upon arrival in market

b) Reduced quality when fruit is held for an extra 2 weeks in market before ripening

Ensuring fruit leaves the packhouse at the recommended temperature sets the scene for the rest of the journey. Refrigerated trucks are not designed to pull the temperature down if the fruit is loaded too warm.

Real-time data loggers, suitable for monitoring product temperature and location in domestic supply chains, can cost as little as $50. The information they can provide can enable you to monitor and manage your consignments with your marketers. Fruit that may have reduced shelf life due to poorer temperature management can be pushed through to retail as a priority, ensuring it reaches the consumer in optimum condition.

Within the supply chain component of the new Monitoring Avocado Supply Chain Quality (AV22011) project, avocado consignments will be sampled and handled in two ways:

- Standard treatment – Taken from the commercial ripener and kept at 20°C until medium-soft ripe before quality assessment.

- Challenge treatment – Taken from wholesaler, stored for 14 days at the recommended temperature, commercially ripened and held at 20°C until medium-soft ripe before quality assessment.

The Challenge treatment will provide valuable insights into what happens to fruit quality when supply chains are delayed. Where issues are identified, the in-region project staff will be able to provide traceback services and management advice to assist growers and packers to identify methods to improve fruit quality.

For further information on supply chain quality monitoring please contact John Agnew from the Queensland Department of Agriculture and Fisheries (john.agnew@daf.qld.gov.au) or Anne Larard (idm@avocado.org.au) from Avocados Australia.

This article appears as part of the Guacamole 27 October 2023 enewsletter.

Date Published: 24/10/2023