Domestic avocado supply chain monitoring back in action

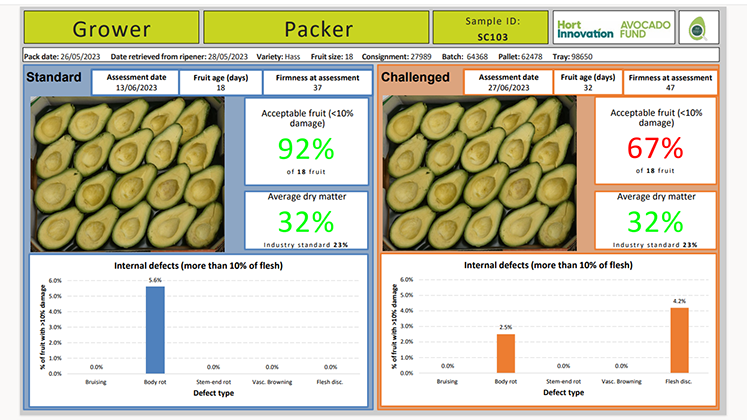

Supply chain quality monitoring recommenced last month as part of the AV22011 project which is delivering a range of project services to increase the proportion of avocado samples that meet industry quality standards. The supply chain quality monitoring component of the project is separate to the retail quality monitoring component. Supply chain samples are being collected from wholesalers and ripening distribution centres, and assessed following a normal commercial ripening program, as well as following a 14-day storage challenge*.

Results from this monitoring are then presented to the supplying packhouse to provide information on fruit quality outcomes under normal supply conditions, as well as under the upper limit of best practice ‘time in the supply chain’ conditions. Approximately 75 domestic avocado supply chains will be monitored each year. The monitoring re-started in early-November, and fruit is currently being sampled from Tristate and Western Australia.

Results under normal commercial conditions

The average results for all 24 standard samples to date are that 88% met the industry quality standard (i.e. at least 90% of fruit have less than 10% damage). The average time spent in the domestic supply chain was 16 days. The main quality defect observed was body rots. The likely causes of body rots in these samples include ineffective orchard fungicides, absence of a post-harvest fungicide, poor temperature management, wet harvesting, poor field hygiene, and high N:Ca levels in fruit. When standard sample results fall below the quality standard the AV22011 project team work with the packer and supplying grower to conduct a traceback to try and determine the cause of poor quality and suggest possible solutions.

Results under challenged commercial conditions

The results of the challenged samples tests are showing supplying packhouses how this same fruit has been able to hold up with an additional 14 days of storage. To date 62% of challenge samples have been able to continue to meet the quality standard. The challenged sample fruit that failed to meet the industry quality standard suffered mainly or exclusively from diffuse discolouration (refer image below). These samples averaged 30 days in the supply chain. Storing fruit for longer than 14 days even at recommended temperatures (5oC for Hass) can cause diffuse discolouration.

For further information on supply chain quality monitoring contact John Agnew from the Queensland Department of Agriculture and Fisheries (john.agnew@daf.qld.gov.au) or Anne Larard (idm@avocado.org.au) from Avocados Australia.

*Normal (standard) commercial conditions = collected post-ripening, held at 20oC, and assessed at med-soft ripe)

Challenged commercial conditions = addition of ~14 days additional cold storage before ripening, held at 20oC, and assessed at med-soft ripe)

This article appears as part of the 8 December 2023 issue of Guacamole.

Date Published: 06/12/2023