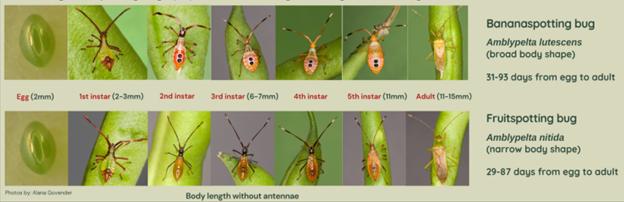

- Both nymphs and adults can cause damage to avocado, only adults can fly.

- Adults lay single, opalescent green, oval-shaped eggs about 2 mm long on fruit, flowers, or leaves, often in hosts other than avocado. They are hard to spot.

- After hatching, the bugs pass through 5 nymphal stages before becoming adults.

- The young nymphs (immature bugs) are ant-like and pink to red-brown with green markings. They have prominent antennae and button-like scent glands on the upper side of the abdomen. These scent glands are most prominent in BSB.

- Adult bugs are brown-green, about 15 mm long, with long legs and antennae. They can be difficult to find because when disturbed, they either fly away or hide.

- Avocados are susceptible to damage anytime from fruit set right through to harvest.

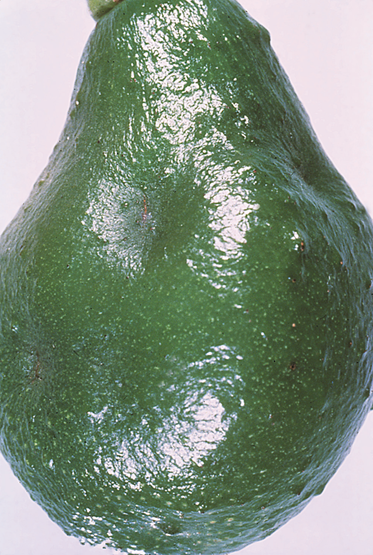

- All varieties are attacked, especially those with thin skins. Due to their corky, pebbled and black skin, late damage is often unnoticeable in Hass until fruit is peeled or cut.

- The bugs insert their long mouthparts into the flesh, inject toxic saliva that digests the cells, and suck out the cell contents.

- Fruit symptoms differ according to the development stage at which they are stung.

- As the fruit grows and expands, stress fractures occur at the sting site resulting in the development of star-shaped cracks, sunken craters, and surface lumps.

- Damage predisposes fruit to anthracnose rots.

- Also, fruit fly will take advantage of stings to lay their eggs.

|

|

|

|

| Very young fruit will fall off if stung | Young fruit may show sunken spots, dimples, or lumps | Fruit that is about half grown and larger will secrete sap which dries to a white powder (a slightly sweet sugar called perseitol) easily washed off by rain | |

|

|

|

|

| In older fruit that is still growing, cracks and craters will develop | In fruit that has reached full size, ‘blind’ stings will develop which are invisible unless fruit is peeled or cut | Small hard woody ‘stones’ can develop in the flesh just under the sting | |

Spotting bugs can be confused with assassin bugs and tea mosquito bugs, and their damage can look like that of fruit fly and tea mosquito bugs. Sometimes fruit fly will lay their eggs into spotting bug stings. Refer to the spotting bug poster for more information.